CLAW LINE - the unique cable fall-arrest system for ladders and structures of all kinds

The new CLAW LINE enables the safe ascent or descent of ladders to reach the required height or depth. The EN 353-1:2014+A1:2017 certified cable fall-arrest system can be installed on the existing structures independently of the ladder or, where required, attached directly to the ladder. The 3 basic systems can be combined with one another flexibly as required. This means that the system offers the right solution to suit the specific circumstances and is EN certified for 8 - 10 mm and 5/16 to 3/8 inch stainless steel cables. With our CLAW runner, users can climb easily and safely up and down the permanently installed system, without having to reattach themselves at intermediate structural anchors. Typical areas in which the CLAW LINE can be used include telecommunications, energy supply, wind turbines, high-bay storage, chimneys, water supplies and sewage disposal.

The CLAW LINE has a variety of impressive features

- Simple planning and installation – the upper and lower anchor points can be selected and combined as required

- Entire system made of high-quality stainless steel (V4A) – top quality and corrosion resistance in the offshore, near shore and onshore sectors, as well as in water supplies and sewage disposal

- The individual elements are packaged extremely efficiently – small pack sizes can easily be transported to the place of installation

- Extremely simple installation – modular system is easy to understand and practically self-explanatory for the installer

- Intermediate supports can be traversed easily with the CLAW runner – making it easier for the user to climb

- EN 353-1:2014+A1:2017, user weight: up to 150 kg

Individually configurable fall-arrest systems

All upper and lower attachment points can be combined with each other as desired. This provides 312 different attachment variants for different rope diameters (8 - 10 mm and 5/16 to 3/8 inch):

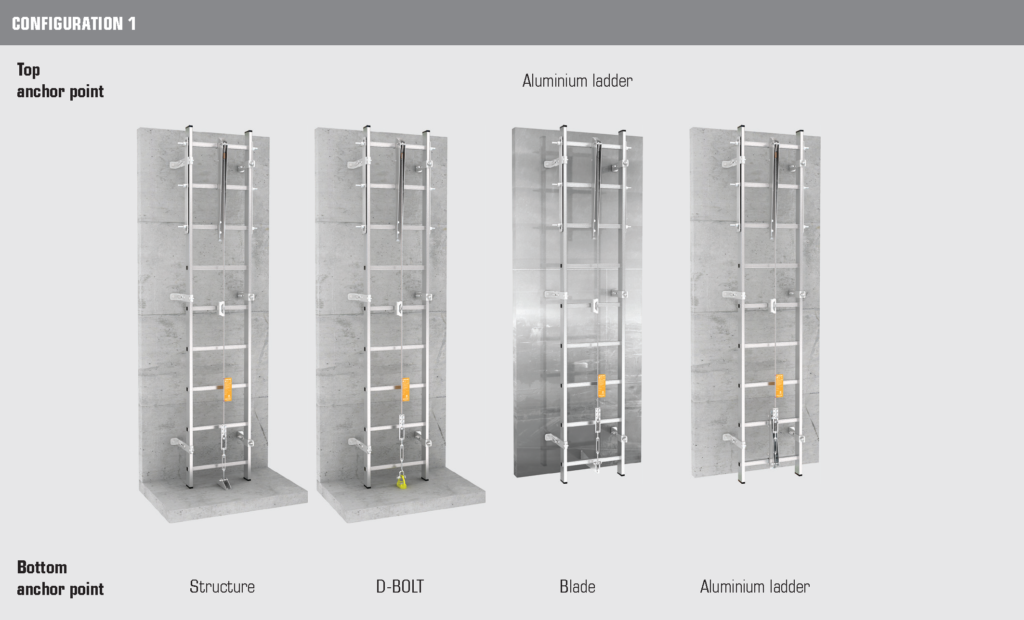

- Configuration. 1

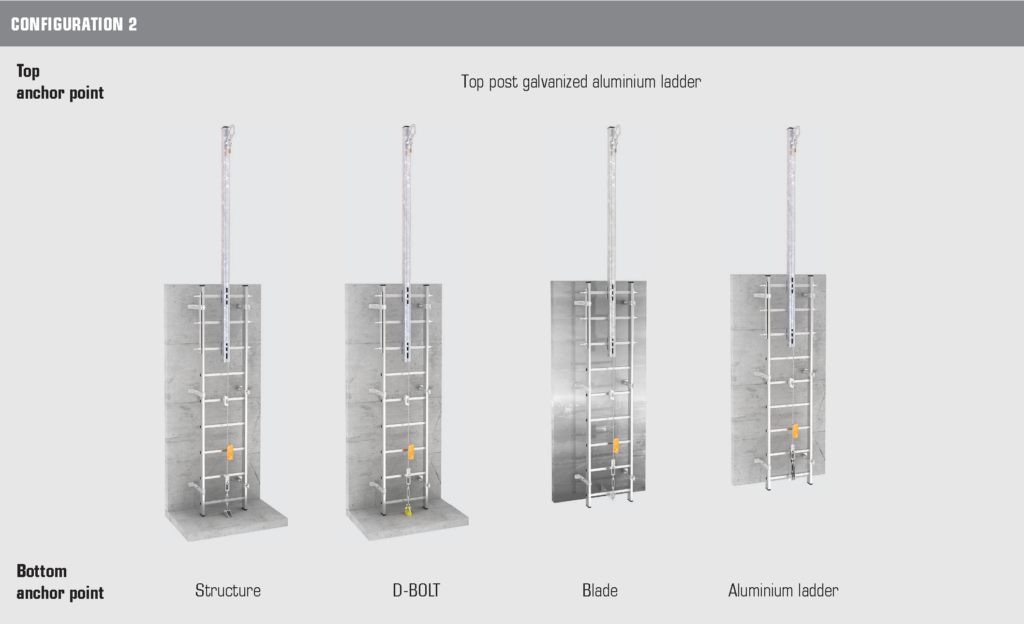

- Configuration. 2

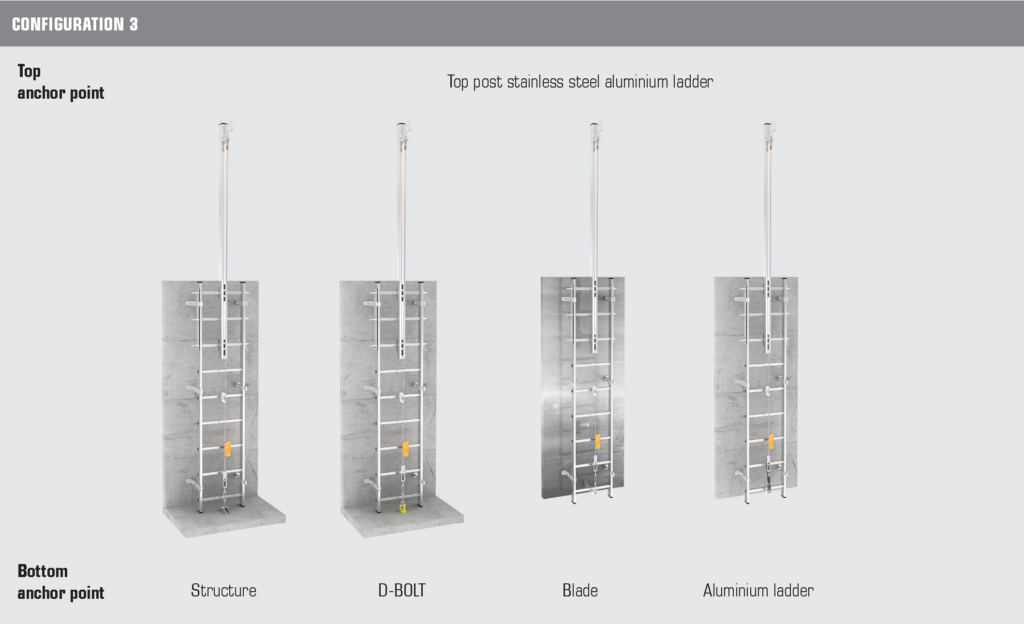

- Configuration. 3

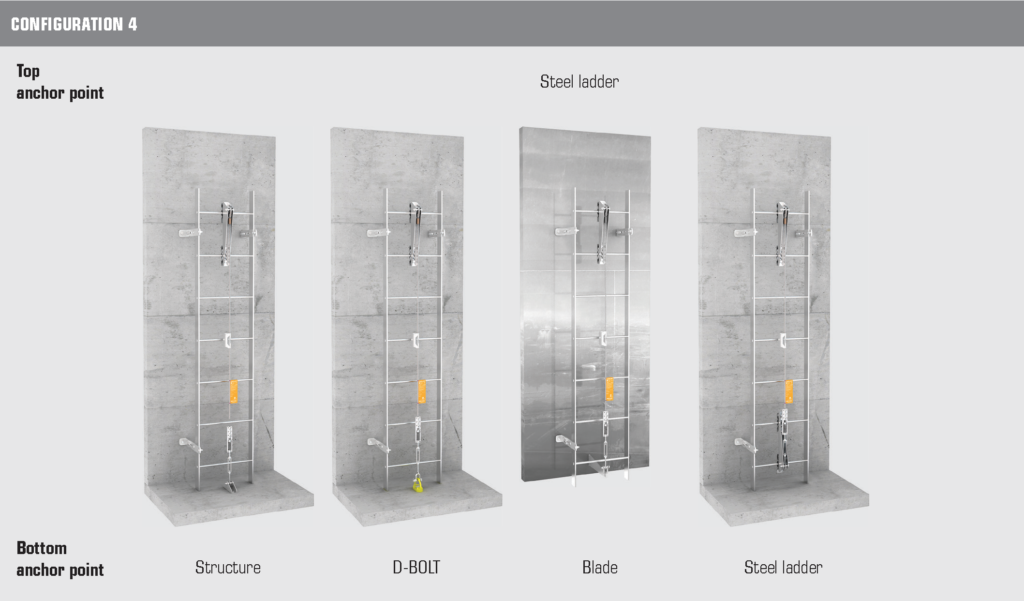

- Configuration. 4

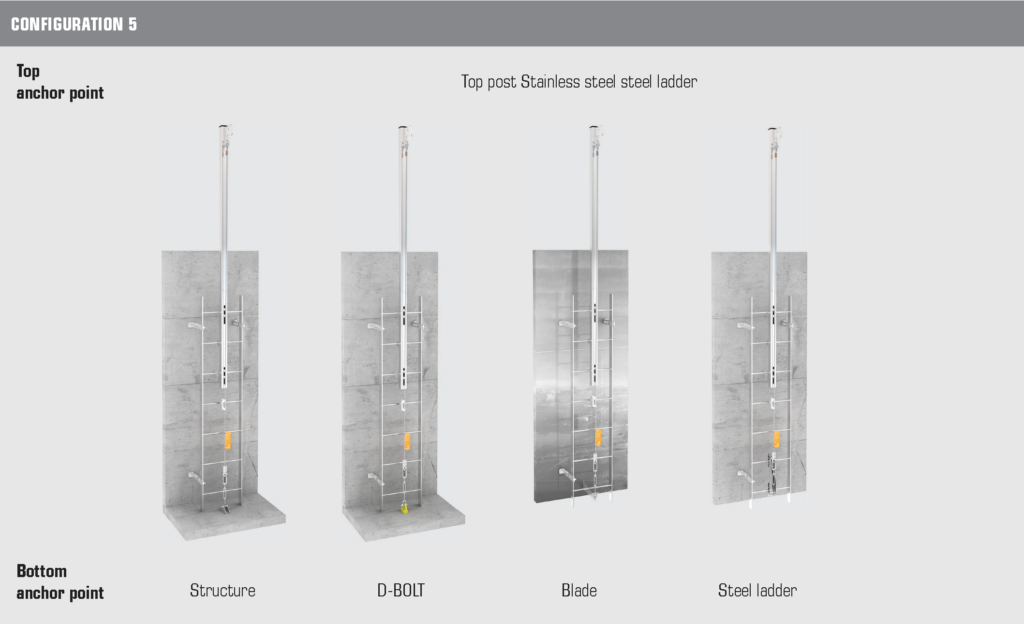

- Configuration. 5

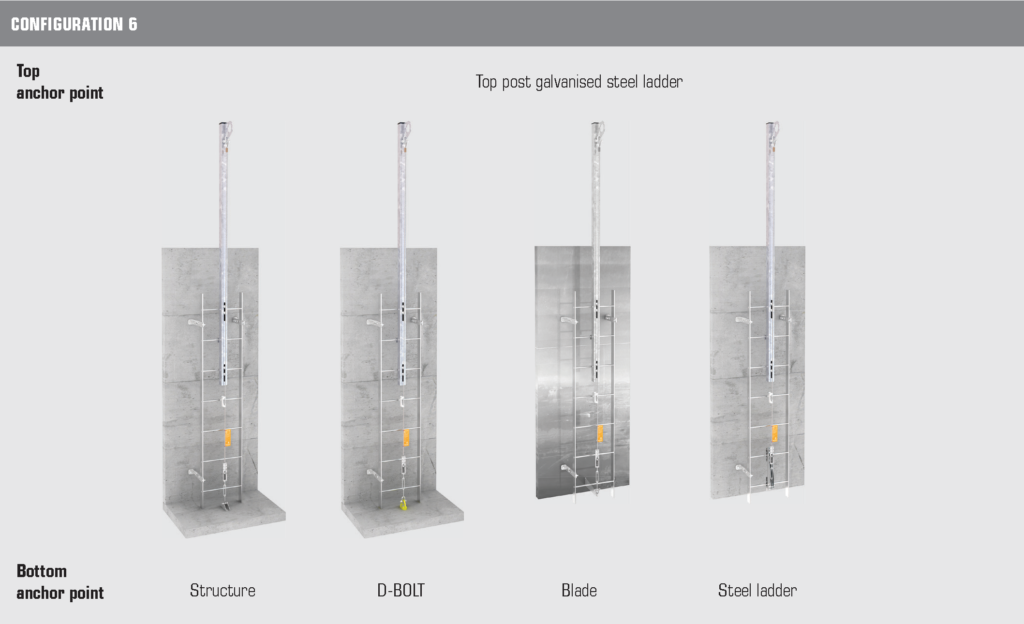

- Configuration. 6

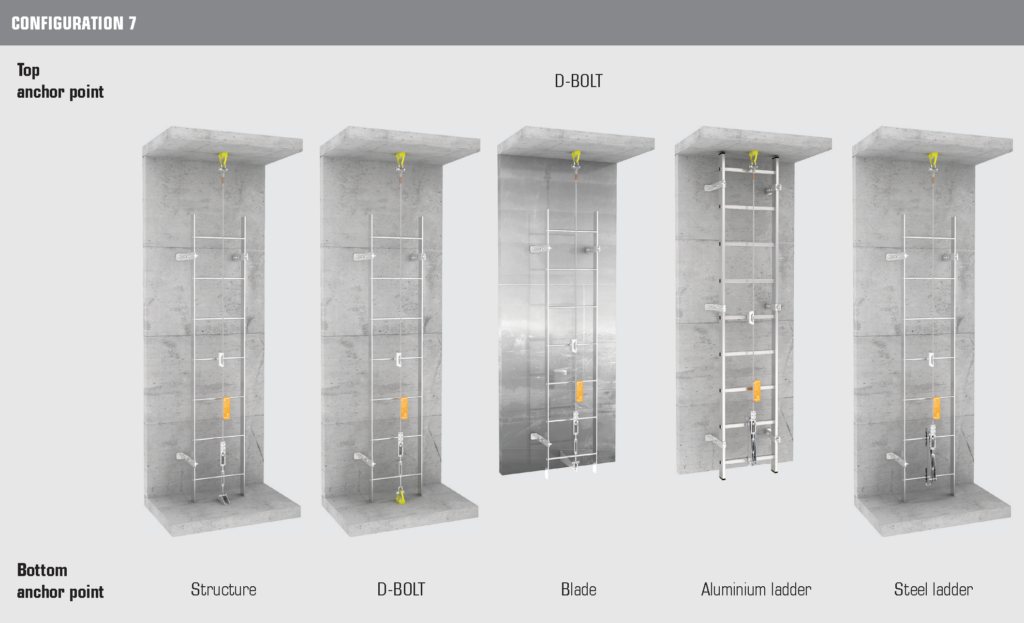

- Configuration. 7

- Configuration. 8

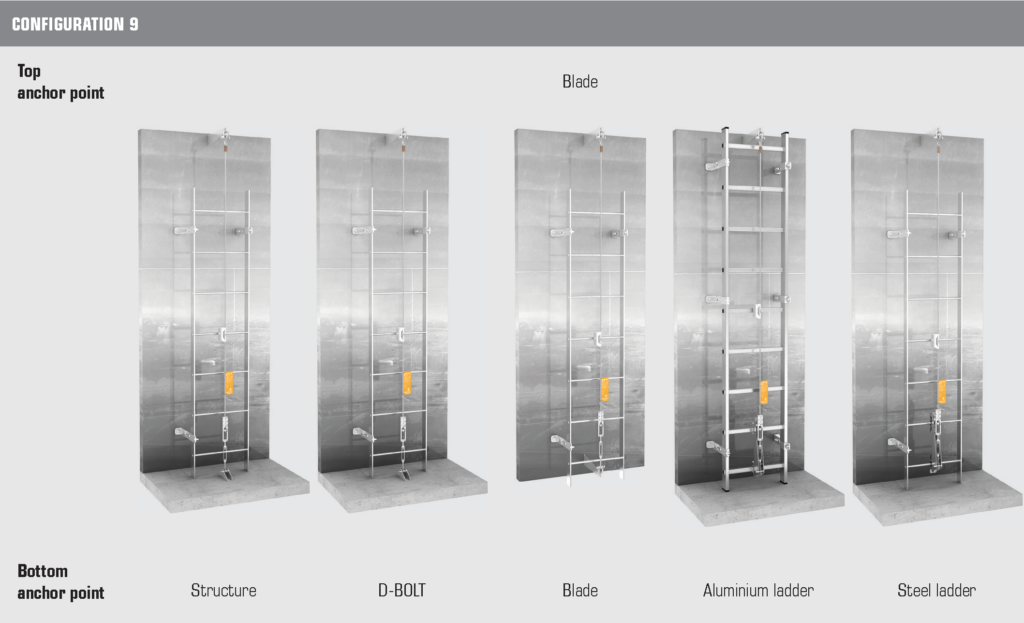

- Configuration. 9

| Upper anchor point Aluminum ladder (3 steps) | Lower anchor point Aluminum ladder Single attachment point (D-BOLT) Structurally tested fixation point Structure |

| Upper anchor point TOP POST galvanized aluminum ladder | Lower anchor point Aluminum ladder Single attachment point (D-BOLT) Structurally tested fixing point Structure |

| Upper anchor point TOP POST Stainless steel aluminum ladder | Lower anchor point Aluminum ladder Single attachment point (D-BOLT) Structurally tested fixing point Structure |

| Upper anchor point Steel ladder (2 steps) | Lower anchor point Steel ladder Single attachment point(D-BOLT) Structurally tested attachment point Structure |

| Upper anchor point TOP POST Stainless steel ladder | Lower anchor point Steel ladder Single anchor point (D-BOLT) Structurally tested attachment point Structure |

| Upper anchor point TOP POST galvanized steel ladder | Lower anchor point Steel ladder Single anchor point (D-BOLT) Structurally tested anchoring point Structure |

| Upper anchor point Single anchor point (D-BOLT) | Lower anchor point Aluminum ladder Steel ladder Single anchor point (D-BOLT) Structurally tested anchoring point Structure |

| Upper anchor point Structure | Lower anchor point Aluminum ladder Steel ladder Single anchor point (D-BOLT) Structurally tested fixing point Structure |

| Upper anchor point Structurally tested anchoring point | Lower anchor point Aluminum ladder Steel ladder Single attachment point (D-BOLT) Structurally tested fastening point Structure |

Assembly steel ladder

Assembly steel ladder TOP POST

Please pay attention to the following points during installation

- A rung reinforcement for aluminum ladders according to DIN EN ISO 14122-4:2010 with a rung size of 30 x 30 mm is included with all relevant system components.

- A clamping element is fundamental for each system.

- Intermediate supports are available to suit requirements and rung type.

Installation of the CLAW LINE

What experts say about the CLAW cable runner?

"I am pleased to announce that ComTrain has completed its in-depth testing of your ladder safety device, “Claw”. As you are aware we evaluate every product with a rigorous three month process that we call ComTested. We are proud to state that we continue to be the largest end user testing experts in the field of communications. Not every product meets our standards, in fact quite the opposite. Our instructors only place approvals on less than 10%.

It pleases us greatly that a manufacturer is attempting to make a new ladder safety cable sleeve. As you are no doubt aware, there just isn’t many others to choose from. We were pleasantly surprised on how well it works. It is much lighter than its competitor. We really like the fact that the hook and arrest package are replaceable. It descends very well although it is a little touchy on ascent depending on cable type and diameter. Although, with the decreased cost and the fact that it has the ability to be maintained, its value supersedes anything in its class. With all this being said it is definitely, as of this evaluation, the best in its field and we will not hesitate to recommend it.

We found this cable grab excels in the following:

- Much lighter than anything in its field

- Tapered opening on top and below the slide allows for maximum efficiency when gliding over obstacles

- Attractive design and coloring (as with all Skylotec brands)

- Field replaceable hook and absorber is a huge plus

- Easy to apply and remove from cable

- Descends the cable without hanging up better than anything in its class"

July, 2018 I Steve Wilcox, Comtrain U.S.A.