Spring is just around the corner, and it’s time for the via ferrata season to begin. Before you set off, however, it is important to check your equipment after the long winter break. Since the equipment used for climbing via ferrata is also PPE (personal protective equipment), SKYLOTEC recommends inspecting it regularly. This primarily includes the energy absorber for use at via ferrata, but also the helmet, the climbing harness, slings, and carabiners.

To make it easier for you to carry out regular inspections, SKYLOTEC would like to present the most important aspects when maintaining and inspecting energy absorbers for use at via ferrata:

- What information is on the label?

- What is the service life of SKYLOTEC energy absorbers for use at via ferrata?

- How can the service life of the energy absorbers for use at via ferrata be increased?

- How can I check that an energy absorber for use at via ferrata is working?

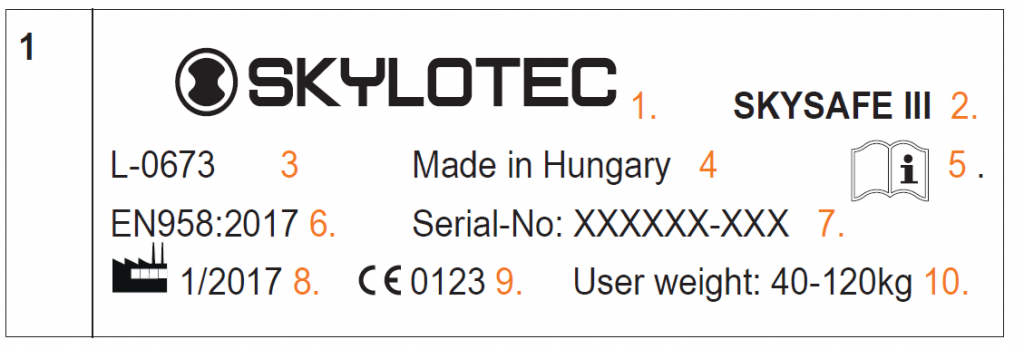

1. What information is on the label?

- Manufacturer

- Product name

- Item number

- Month/year of manufacture

- Place of manufacture

- Note on the instructions for use

- Standard

- Serial number

- CE number

- User weight

What is the most important information for the end consumer?

- User weight including equipment for which the product was tested

- Year of manufacture in connection with the specified service life (see question 2)

- CE number shows that the product has been tested by an independent testing institute

- The European standard (EN) defines the minimum requirements for the product

2. What is the service life of SKYLOTEC energy absorbers for use at via ferrata?

The service life of the product depends on the type of application and frequency of use as well as on external influences. It is important to understand that textiles and synthetics age even when the product isn’t used. For this reason, these must be replaced after ten years at the latest.

The following is a brief overview of the recommended service life depending on use:

- Occasional use (one to two times a month) – up to five years

- Frequent use (weekly) – up to three years

- Professional/commercial use (rental business, almost daily) – up to one year

3. How can the service life of the energy absorbers for use at via ferrata be increased?

Storage and transport

The set should be stored in a dry place away from direct sunlight. When storing in basements or in the trunk on the way to the via ferrata, care should be taken to avoid proximity to substances containing solvents, as these can eat away at the textile fibers and lead to failure of the energy absorber for use at via ferrata . Gasoline, diesel, antifreeze, and acids of any kind (battery acid in electric cars) can lead to total breakdown of the material.

Cleaning and care

If heavily soiled, the flex arms can be rinsed with lukewarm water by hand using a soft brush. Please do not use aggressive soaps or detergents. The set should be dried at room temperature but not in a clothes dryer, on a heater, or in direct sunlight. UV radiation damages textiles and makes them age faster.

If a carabiner is difficult to move or is dirty, it can be cleaned with water using a soft brush and a resin-, silicone-, and acid-free oil (e.g. Ballistol Universal Oil) so it moves smoothly again. Please make sure that excess oil is wiped off and does not come into contact with the webbing material of the flex arms or the energy absorber.

The accompanying steel cable clamp of the RIDER 3.0 can be cleaned like a carabiner so that it moves smoothly again. Dust and dirt are removed from the device with a soft brush, and the moving parts are carefully oiled. Please make sure that excess oil is wiped off and does not come into contact with the webbing material of the flex arms or the energy absorber.

Maintenance

A careful visual and tactile check of the complete equipment must be carried out before and after each use of the energy absorber for use at via ferrata

- Seam patterns

- Connections to metal components

- Discoloration

- Deformations

4. How can I check that an energy absorber for use at via ferrata is working?

Energy absorber

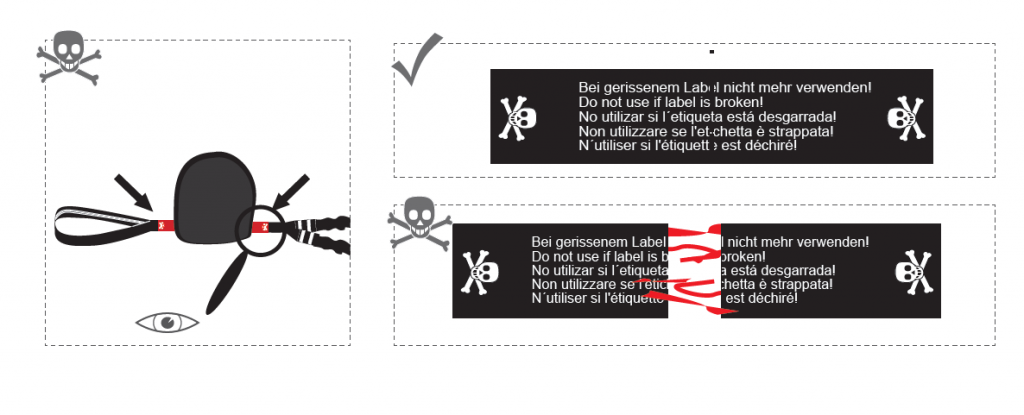

- Open the energy absorber bag

- Inspect the tear-off label: If it is torn, the energy absorber for use at via ferrata must be removed from use because the energy absorber has been damaged and cannot absorb any new energy that it is subjected to. Once the energy absorber has been activated, the complete energy absorber for use at via ferrata must be replaced. Even minor falls can cause the seams to tear open.

- Inspect the seam of the tie-in loop

Textile and metal

| Textile inspection | Metal inspection |

| Knots (1) | Rust on functional parts |

| Cuts (2) | Ease of movement |

| Torn threads | Tears/missing connecting parts (10) |

| Frayed or worn down areas (4) | Manipulation |

| Foreign substances stuck to material | Chipping |

| Manipulation (6) | Alignment of the slipping mark of the axle |

| Marking (7) |

Equipment needs to removed from use immediately in the following cases:

- After a fall (extreme mechanical stress)

- After activation of the energy absorber

- In case of damage to the display label sewn into the energy absorber

- After a high thermal load, contact with friction heat (signs of melting)

- In the event of irreversible, heavy soiling

- After contact with chemicals

- If a carabiner is damaged/defective

If you are not confident that you can perform the inspection yourself, SKYLOTEC offers the service of having your PPE inspected once a year by a qualified professional. You can learn more about this here.